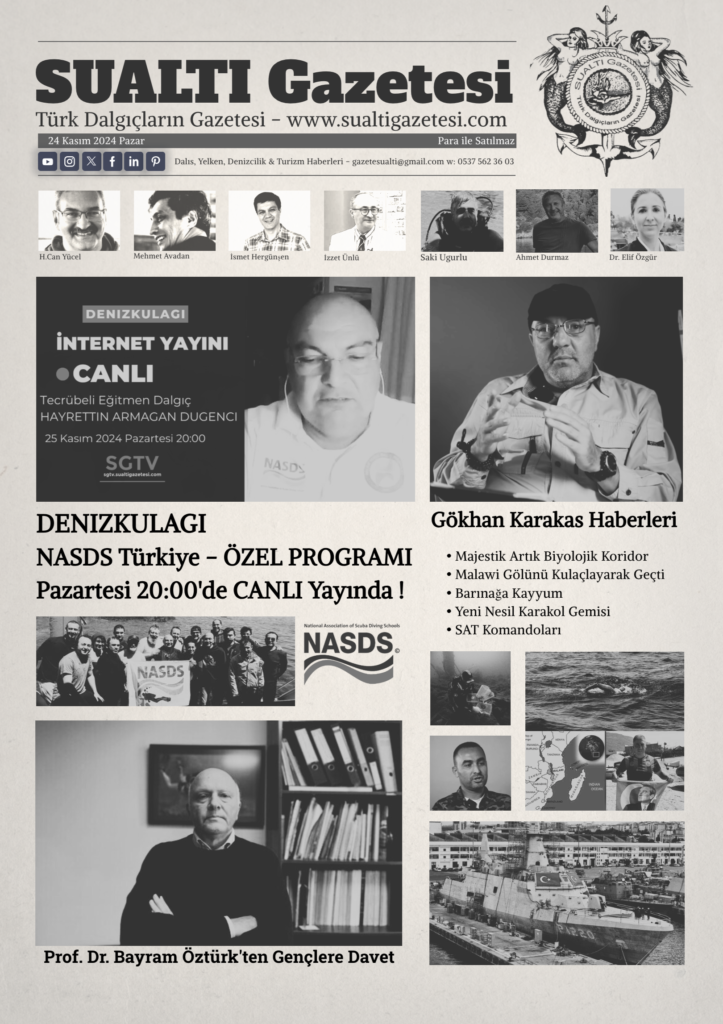

In the exacting, precise high tech world of ocean racing yacht construction the CDK boatyard are a benchmark operation. Created in 1984 by Hubert Desjoyeaux, Jean Le Cam and Gaétan Gouérou, and managed by Philippe Facque, the yard builds all different types and classes of ocean racing craft including Ultimes, IMOCAs, Multi50s and MOD70s. Over recent years their successful IMOCA builds include Michel Desjoyeaux’s 2008-9 Vendée Globe winning Foncia and Francois Gabart’s 2012-13 Vendée Globe winner MACIF.

Looking ahead to the Vendée Globe 2020, CDK have already completed Jérémie Beyou’s new Charal and are building Arkéa Paprec for Sébastien Simon and Apivia for Charlie Dalin. A fourth IMOCA, the new Corum of Nicolas Troussel is on the stocks.

The units at the entrance to Port-la-Forêt are slightly anonymous, unprepossessing even, considering the number of famous French ocean racing yachts which have been built here. On the staircase leading to the office, the nerve centre of the operation, is a big portrait of Hubert Desjoyeaux, the co-founder who sadly passed away in 2011. But his founding principles still underpin the operation.

“Hubert’s expertise and aura was a great draw, to the point that he would refuse a job if he felt his client was on the wrong track. Says Michel Ollivier, the technical director of CDK, “It is a bit different now because you deal with the whole teams rather than just the skipper, so there is less likelihood they are on the wrong track.”

Tell us more about changes in the relations between the boat builder and the teams…

“This is without a doubt the biggest change of recent years. Ten years ago, the yard personnel had a direct relationship with the skipper who pretty much dictated the boat he wanted. Then it was between the yard, the designers and the sailor. Today, the technical teams of the big teams are bigger, stronger and more specialised. A team which realistically is looking to build a Vendée Globe winner comes with their own in house designers and young engineers who work permanently on the project. It is they who we deal with day to day much more than the skippers themselves. ”

So the roles and responsibilities have changed?

“Clearly. The new generation of skippers is more interested in the performance of the boat and its subsequent optimization. Before, sailors Jean Le Cam, Michel Desjoyeaux and Vincent Riou and others of their ilk were much more involved in the yard. Today, the skippers delegate most of the day to say stuff to their design office. These roles changed more as the boats are so much more complex. There is not comparison in terms of the technical level of today’s latest generation IMOCA and even the likes of the 2012 Vendée Globe winner MACIF of François Gabart ”

How do builders like yourselves adapt to this new way of working?

“First of all we try to be as clear as possible in terms of planning and communication upstream. The preliminary project is defined, the scheduling and the technical choices are laid out. That allows us to make a proposal for the quote and the work schedule. Such data will be adjusted according to the final delivery of the design plans by the architects. The yard then allocates two people who will be the main liaison with the team. We will have discussions on technical choices, the feasibility or otherwise, the objective being to be offering as much constructive input as possible early on.

Then during the build a detailed progress report is made every 15 days. We fine tune and flag up any financial differences, how the schedule changes. And we host site meetings with the team keep everything smooth and everyone up to speed. Construction of a boat sees everything constantly evolving according to small refinements and ideas coming from the team and It’s up to us to adapt. In the end it is always the customer who has the last word. ”

How many man hours does it take to build an IMOCA?

“Today it is between 28 and 30,000 hours to make the “ box ” that’s the hull and deck without the appendages. The days are long gone when the yard built the boat from start to finish, from A to Z. Iinstallation, rigging, deck hardware and so on is done and managed directly by the teams technicians. Basically, our job – making the ‘box’ – is about half of the construction of the boat as a whole.

And how much does you part of the build cost ?

“We reckon an average of under two million euros. ”

The appearance of the foils means big changes in hull construction?

“Yes, not just because you build a boat around your foil. The fact that the hulls fly require the impact zone to be strengthened. Now the slamming is more violent and the impact zones have evolved, moving further towards the back of hull. At the same time, we try to make hulls lighter and lighter. That’s where the art and science of a good compromise comes in. And we must also take into account the time factor. We are now less than two years from the Vendée Globe and these boats require a long and complex build up. Skippers must be able to spend a lot of time on the water. This explains why they call on former skippers as project managers. The expertise of a Vincent Riou, a Roland Jourdain or a Michel Desjoyeaux can save a lot of time in the preparation for the Vendée Globe. ”

Today, the CDK yard has several boats in build designed by different architects, how does this work in reality?

“I cannot reveal much, but the fact is that choices made by different offices are still very different from each other. I think you would be surprised. But it is only on the water that we’ll know who’s right. For the IMOCA class and for the Vendée Globe that’s exciting.”

Source: Vendee Globe